Kirish

Break through the limitations of the original worktable,using swing welding head Any Angle welding, welding seam width adjustable, replace the traditional argon arc welding, Electric welding process, simple operation no need for welding certificate.

Texnik parametrlar

Model.No | DTW-500W | DTW-1000W | DTW-1500W | DTW-2000W |

Operating Mode | Continuous/Modulation | |||

Lazer to'lqin uzunligi | ±2% | |||

Power Requirements | 220V | 220V/380V | 220V/380V | 220V/380V |

Machine Power | ≤5KW | ≤7KW | ≤9KW | ≤11KW |

Operating Environment Temperature Range | 15-35 ℃ | |||

Working Environment Humidity Range | <70% No Condensation | |||

Welding Thickness Range | 0.5-0.8MM | |||

Welding Line Requirements | ≤0,5 mm | |||

Payvandlash tezligi | 0-120 mm/s | |||

Mashina hajmi | 1190×1100×650mm | |||

Laser cutting sample

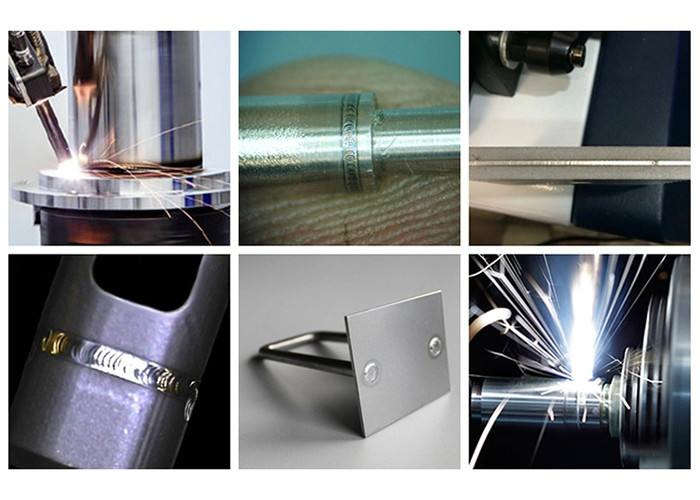

✦Applicable Materials: Leapion laser welding machine Application in Stainless steel, Carbon steel, Aluminum, Copper materials, etc.

Xususiyatlari

Hand-held welding gun operating mode, can be welded to any angle of any part of the work piece.

Hand-held welded head is equipped with 10 m fiber, flexible and convenient can achieve outdoor welding.

Applicable to various complex welds, spot welding of various devices.

Ishlash oson

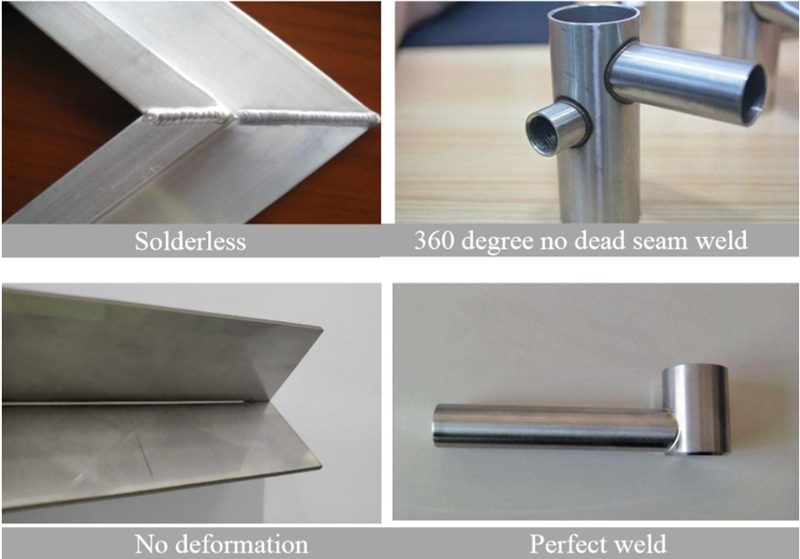

Simple and easy to operate, no deformation of the welding seam, stable laser output to ensure welding consistency, high power density after laser focusing, fast speed, great depth and small deformation, 360-degree micro-welding.

Chiroyli payvandlash jarayoni

Asl dastgohning cheklovlaridan o'tib, u barcha turdagi murakkab payvandlash tikuvlari uchun javob beradi va ish qismining istalgan qismini istalgan burchakda payvand qilish oson. Insoniylashtirilgan dizayn va texnologiyani yangilash chiroyli payvandlash tikuvlarini payvandlashi mumkin.

Kichik tanasi, samarali payvandlash

The welding speed of laser welding machine is 3-10 times that of traditional argon arc welding and plasma welding. The welding heat affected area is small, and it will not cause problems such as deformation, blackening, traces on the back of the joint construction, and the welding depth is large, the melting is sufficient, and the welding is firm.

Ikki qo'zg'aluvchan qo'lda aylanadigan lazerli payvandlash boshi

Turli xil payvandlash ehtiyojlarini qondirish uchun 6 ta payvandlash rejimi va bir nechta payvandlash nozullari mavjud; u xavfsizlik sensori funksiyasiga ega, u metallga tegib ketgandan so'ng lazer chiqaradi va uni olib tashlanganda yorug'likni avtomatik ravishda qulflaydi; spiral jitter funktsiyasi, payvand chokining kengligi sozlanishi va payvandlash qobiliyati sezilarli darajada yaxshilanadi.

360 ° O'lik burchakli mikro payvandlash yo'q

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned, and is applied to micro and small workpieces that are automatically produced in large quantities. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, stitch welding, tailor welding, sealing welding, etc. High aspect ratio, small weld width, small heat aff